Zena Forest Products’ co-owner, Ben Deumling, grew up roaming around his family’s 1,300-acre forest in the Willamette Valley, which his family has managed since the 1980s. In 2007, Ben and his mother, Sarah, built a sawmill to make hardwood flooring from white oak and maple harvested from the Deumling's land. Zena Forest Products is now the largest “forest-to-floor” company in Oregon.

When PDX hired Zena to manufacture white-oak floors for the main terminal, Ben and Sarah took another leap of faith: They became the first company in America to make edge-grain floor tiles using smaller trees, which they cull from their land to make the remaining forests healthier.

This interview has been edited for concision and clarity.

How did you go from managing a forest to making hardwood floors?Our forest is a classic Willamette Valley mix of Douglas fir, Oregon white oak, and Western big-leaf maple, plus a few minor species. But [in the early 2000s,] the only thing that generated revenue was selling Douglas fir logs. Conventional wisdom said: Cut down your hardwoods and plant fir. We didn't want to do that.

We're really glad we didn't, because in our changing climate, the Doug fir is really struggling in a lot of forests, and the oak is thriving. It’s probably the most climate-resilient species we have on the West Coast. Flooring is really the best suite of products that we can make out of these trees.

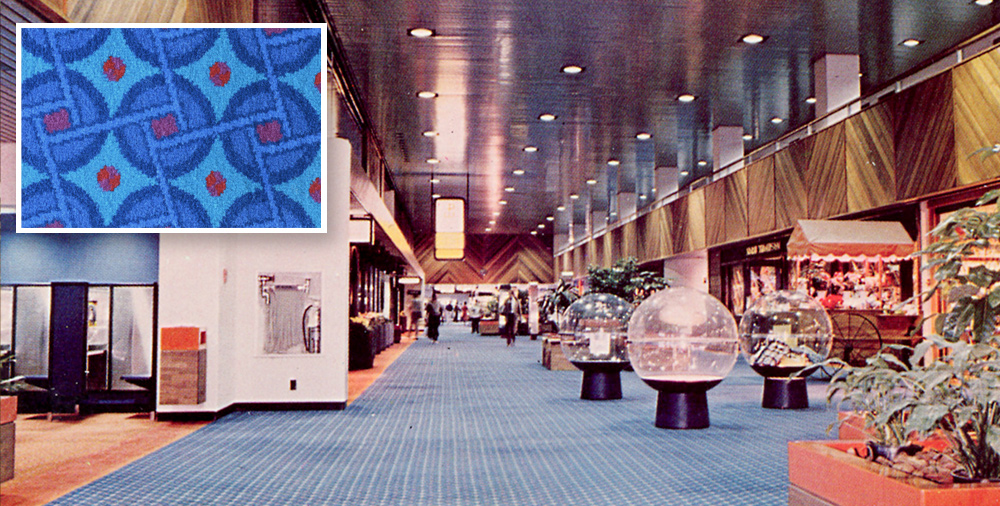

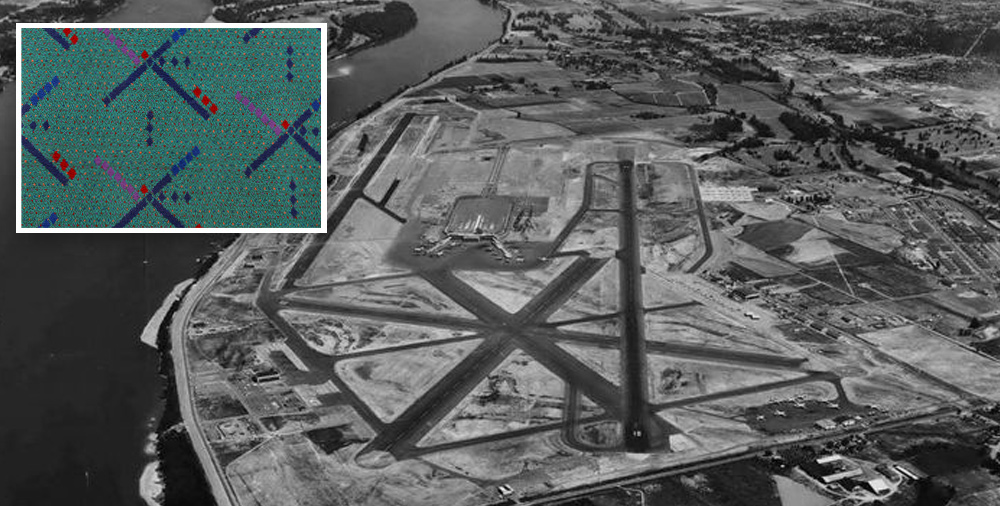

For PDX, you came up with a new way of making hardwood floors?Traditional flooring is made up of strips of lumber, displayed face-grain up and joined tongue and groove. Everyone wants wider, longer boards. The edge-grain floors we're making for the airport are tiles made up of little sticks held together with wire on the undersides. (Editor’s note: “edge-grain” means the tiles display the sides of the boards, not the top “face” grain.) It was a new, innovative look that the architects at ZGF loved.

No one in North America makes edge-grain floor tiles. I had seen samples of them, but when I pitched the floors to PDX, I had no idea how to make them. [Laughs.] We made our initial prototypes on a table saw. We cut little sticks and taped them together with Scotch tape.

We bought all the machines from a manufacturer in Germany that specializes in making equipment for edge-grain floors. Then we set up a new facility.

When you say ‘little sticks,’ are you using scrap wood?Yes. Some of it was scrap, and some of it was thin strips of wood we were making into countertops and cutting boards. This wood was piling up [at the sawmill], and it was not something that moved very easily.

Half. The other wood we source from a 60-mile radius around our mill. It’s primarily coming out of other forest restoration projects. I like to use the small leverage that I have, our purchasing power, to incentivize good stewardship and retention of oak on the landscape.

Is your mom still involved in the business?She’s 77, and she’s in the forest every day. She just planted 200 alder seedlings over the last three days.

What did it mean for you and your family to build this floor for PDX?PDX was our first customer [for this edge-grain flooring], and probably the biggest customer we’ll ever have. Now we have this facility, and we’re experimenting with lots of different tree species and different tile patterns, figuring out what all we can do with this technology.

When you look at forestry in Oregon, and where forest management is going, so much of it is about restoring forests. In that restoration work, you’re taking out a lot of little trees to let the forest keep growing. But it's hard to saw them into lumber. The flooring tile that we're making is a phenomenal home for these small trees. We're just starting to scratch the surface of where we can go with this.

By investing in Zena Forest Products, PDX has actually made a long-term investment in forest restoration in Oregon.